Stock is never enough

As I’ve already mentioned, for these guys stock speed is NEVER enough, and the modifications to the cooling setups on the provided motherboards and graphics cards were obviously very extensive. For the majority of us, overclocking means a high end air cooler or at most a water cooling setup, but the cooling abilities of these pale in comparison to what is demanded in the world of extreme overclocking.A look over the forum at Benchtec reveals everything from Ethanol filled subzero watercooling, to three phase cascade coolers (similar to the Prometia phase change units some of you might have seen, but with 3 cooling phases to cool the CPU to sub -150°C), but the king of the overclock has always been liquid nitrogen.

Evaporating at -196°C (thanks Wikipedia!), it provides the best solution to brute force cool CPUs and GPUs to super-chilled temperatures, but getting it in contact with the thermal interfaces of the processors requires some serious kit, most of which consists of copper, and lots of it. These solid copper coolers, dubbed “pots” can weigh well in excess of 3 kilos, and differ enormously between teams.

Some use pre-made coolers, built by specialist manufacturers for the sole use of liquid nitrogen cooling, while others will custom mill their pots from copper blocks or copper pipe. Although all have a copper base around 2cm thick to maximise cooling potential of the pot, the internal surface area differs greatly between setups dependant on individual overclocker style and approach.

Click to enlarge - Team Portugal's setup and team Australia's Franken-card, using both stock and custom cooling

GPU pots are even more complex, as the GPU is always at 90° to the motherboard, meaning the pot must attach to the card’s stock cooler mounts. This caused some serious problems, as most team’s GPU pots hadn’t been designed to attach to the GTX 280 card, meaning some late night drilling was needed to mount the various GPU pots to the provided cards.

As well as the monstrous copper pots on display (which were more than capable of ambient cooling the processor!) every team had a different approach to cooling the other motherboard and Graphics card components. The Brits were the only team to choose an LN2 solution for their Northbridge, meaning their basic setup had three separate LN2 pots! This meant some serious devastation was wrought on the motherboard cooler’s heatpipes as the Northbridge cooler had to be completely removed. Other teams were packing the favourite of the overclocker – lots of ultra high CFM Delta cooling fans (watch those fingers!) to improve airflow over motherboard chipsets or redirect LN2 vapour down on to / away from the motherboard.

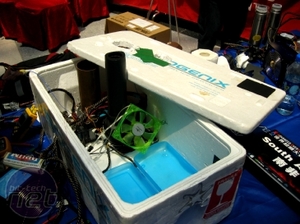

Click to enlarge - Team South Africa's Ingenious solution - stick your setup in a sealed dry ice cooled box!

The stock graphics card cooler also met the hacksaw, with many teams keeping parts of the stock cooling solutions for the PWMs and display output controller chip, which are then ambient cooled to sub zero levels as the GPU reaches temperatures lower than -150°C. Other teams used custom cooling setups, with mini-heatsinks particularly popular, and China even bringing their own custom machined graphics PWM heatsink!

There really was a vast difference between team cooling setups, as some obviously prioritised different components for additional cooling. However, what was generally accepted as the most innovative cooling setup on show was Team South-Africa’s, who had placed their entire system, pots and all, into an insulated Styrofoam box, which they then filled with fan assisted dry ice. A motherboard temperature of -20°C without even using LN2 was pretty impressive to say the least!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.